Brian Flint is an electronics design engineer, who began working at Sinclair Radionics Ltd in St Ives, at the start of 1971, eventually moving to Sinclair Research in Kings Parade, Cambridge, where he stayed until 1981. The projects he worked on include the hi-fi range of products, pocket and flat screen TVs and the ZX80 and ZX81 home computers. He recalls his experiences working for one of the UKs most notoriously innovative and self-destructive 20th Century technology companies.

By the time I left Sinclair Research, the ZX80 was on sale and I was working on its successor, the ZX81, which involved reducing the number of low-power Schottky TTL chips and putting them into one programmable IC – an uncommitted logic array – which was made by Ferranti. There was something like ten TTLs in the ZX80, which all had to be reduced into one IC. That all went ahead and meant that, because fewer components were inside the ZX81, it was more cost-effective than the ZX80. My job at that point was to help with the engineering and check that it was going to work.

When I joined the company was called Sinclair Radionics and was in Enderby’s Mill in St Ives. My position was Electronics Design Engineer, and I worked in R&D. I got the job because I had experience in television design from working at Pye/Philips in Lowestoft, and virtually the first project I was put on at Sinclair Radionics was the development of a miniature television set.

At that time the only products they had on sale were hi-fi products, including a stand-alone FM tuner, a power amplifier and some kits. The kits comprised components which people could fit into the plinths of a record player to add a preamplifier or whatever it might be. The record players at that time usually came with a wooden plinth so you would cut holes in the plinth and bolt these bits and pieces on the front. Believe it or not, that’s what people did! Apparently there was a market for that, although not much of one, I suppose. The company sold a stand-alone amp as well, just to cater for a different market.

Early Days at the Mill

I joined Sinclair Radionics immediately after leaving Pye/Philips. Pye/Philips was a large company and I just didn’t see myself carrying on there. I felt that I needed to get into design with another company. The job I originally applied for wasn’t at Sinclair Radionics, but with another company who were based elsewhere in the St Ives mill grounds and made some sort of instrumentation.

I went for an interview but didn’t get the job. I thought that was the end of it, but then I was contacted by Clive Sinclair asking if I’d like to come for an interview with him. I’d got the first interview through a recruitment agency called Cambridge Recruitment and he must have found out about me from them.

Sinclair had noticed that I had experience in colour television set design working for a major TV manufacturer. He was developing his own television set so he was on the lookout for anyone who could be useful. Although I was still a pretty young engineer – about 25 years old –I already had a certain amount of experience having started working at Pye’s when I was 15. He interviewed me personally, we had a chat and that was it, I got the job. I must have said the right things.

When I joined there were about four other electronic engineers there already. There was John Nichols who eventually left and formed Thurlby Thandar Instruments. Thurlby and Thandar were separate companies that originated from Sinclair Instruments when the company broke up in about 1978, but they still had links with Sinclair. Thurlby and Thandar eventually combined and changed their name to TTi.

Then there was Chris Curry, who later formed Acorn, Jim Westwood, who’s a very good practical design engineer, and another chap called Keith Pauley, who left in about 1973 and is now a Production Director at TTi. Plus there was the chief engineer, and my immediate boss, Martin. He was there from about 1970 to 1973, then left to work for an audio manufacturing company making power amps and quadraphonic amplifiers, but I don’t think they lasted long.

It was a very young team; we were all kids really. Jim Westwood is younger than I am; Chris Curry is about the same age, as is Keith Pauley. Martin was about five years older, possibly in his late 20s, and Sinclair was in his early 30s. All of those people were doing electronics to some extent, but there were other departments, including accounts, stores and various people in the test department downstairs.

Our R&D department was on the top floor, as was Clive Sinclair’s office, which was at one end overlooking the river. The upper floor had these cubicles set up, with a door, two benches inside and a window. Me, Keith, Chris Curry, and possibly John Nichols, were crammed in one of these, which was only a few meters across. Martin was in another one on his own.

It wasn’t compulsory, but for a while after I joined we used to wear technician’s white lab coats to protect our clothes, and the company had a laundry system where they would all be collected and washed at the end of the week.

Some of the floors were not occupied at that point, but filled up a couple of years later when the company grew. The first time I saw someone cycling around on an early C5 prototype was on the top floor of the mill and would have been within a year of me joining the company. I didn’t realize that what I saw was eventually going to turn into a car!

Television Time

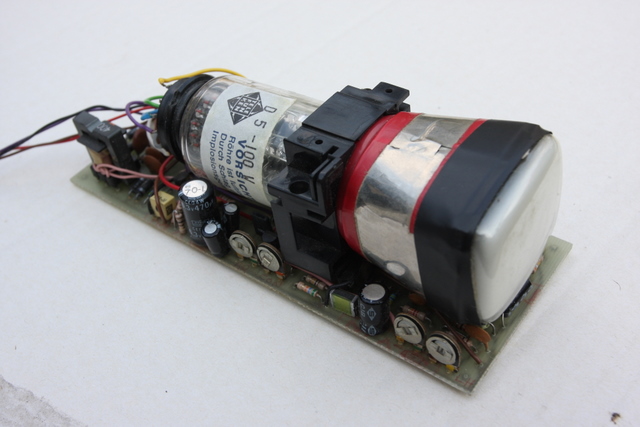

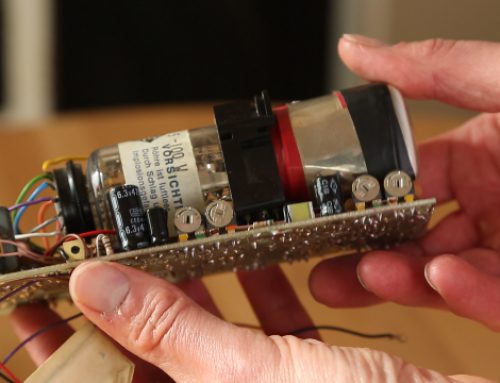

When I joined the main product was the hi-fi equipment, but some design work on the miniature television set had already been going on. There was a set of IC chips that had been designed for it which we were waiting to come in from Texas Instruments. They were the company who were manufacturing the chips for us.

I’m not quite certain who’d designed the ICs. Maybe some of it was done by Sinclair himself, or possibly an engineer at Texas Instruments. Whatever the case, the television’s next stage of development was dependent on this set of three or four ICs arriving.

Sinclair Radionics were also developing their own cathode ray tube for the TV, which they were having made by a little factory in South London. There was a chap down there who was helping organize a small prototype production run and he sent bits and pieces to us.

Those tubes were unusually shaped like a coffin, but we had problems with the vacuum inside. If you get a few parts-per-million of air inside a tube, when you put high voltages on it – I’m talking about one or two KV – the air becomes very conductive, like a piece of copper, and causes the thing to short out! All the ions shoot down the tube, it flashes over and blows up all the semi-conductors, and that happened when I was testing it.

I’d painstakingly built all these little frame and line oscillators and EHT circuitry to go around the tube and had been working on it for weeks when one of the coffin tubes arrived. I very tentatively connected it up to the tube and as soon as the EHT 2KV was applied it flashed over internally and blew up all the transistors and half the board.

The lot went in one go. It was a bit of a set back and I’d only just joined the company. As time went on I learnt that if we had a tube that was likely to flashover, it was good practice to put protection resistors in the circuit at various places so that it could withstand the flashover – but when I first started I didn’t appreciate that such a thing could happen. I think I had a bad moment over it and might have almost walked out. I can’t remember exactly, but I was pretty upset!

The Trouble with Tubes

A tube has various metal plates in it which deflect the electrons as they travel, but the ones in this design weren’t mounted very well, so if you got hold of the tube and subjected it to a little bit of G-force, the plates would move a few millimeters which is an absolute disaster, because you are trying to get the electron beam to hit the middle to the nearest millimeter. That was all badly thought out and wasn’t fully appreciated until after somebody had been working on the tubes for about two years! It was something fundamental that just hadn’t been noticed.

The development of the televisions was over a very long period of time and it was another four or five years before anything went on sale. By that time they weren’t using a tube designed or made by Sinclair Radionics; it was a Telefunken tube made in Germany. Telefunken made television tubes for big TV sets, but also had these little ones, maybe designed for military use.

I went over to Germany at one point to take a look, but we also spoke to Thorn in North London who also made them and we were talking to them about it for quite a while. But we switched to the Telefunken one because they seemed to respond more readily to our requirements. It was about 1974 when we eventually switched.

The Telefunken tube had a specially designed low heater for heating the cathode element, and used about 50mW, whereas the Thorn tube used a 500mW heater, which was over half the power consumption of the whole TV set.

Eventually, after the set back with the dodgy tubes, the chip set arrived from Texas Instruments and were put onto a little circuit board. But unfortunately they didn’t perform as well as everyone was hoping. To find out what was necessary to get this chip set working, produce a finished product and sell it, Sinclair recruited an engineer called Adrian Espin from Texas Instruments, who was experienced in televisions.

Adrian became the project’s Chief or Senior Engineer. While he was sorting out the problem with the chips, I stopped work on the television. I remember it was two months leading up to when I got married in October ’71. I moved to production, which was downstairs in the same building, and was testing and overseeing the first production run of the Executive Pocket Calculator. There were quite a few failures so I was fault finding, testing them and seeing them through. Eventually the company was making a whole range of calculators, but this was the first one. You could slip it in your shirt pocket and it sold for £80, which is a phenomenal amount of money for a calculator!

There were various people working on the calculator design including Jim Westwood. They also had a mathematician, Nigel Searle, doing the algorithms. The chips were being made by Texas Instruments once again, but we still needed Nigel to work out the programming and select which mathematical algorithms to use to do the scientific calculations.

After a while I felt like they had forgotten about me and had to ask to go back into the lab again. The company’s focus was on the calculator, lots of people were involved and Sinclair Radionics expanded as a result of it, but they needed an engineer to oversee the hi-fi design. So I moved back upstairs and started getting into the hi-fi products, which included an FM Tuner and power amplifier. The hi-fi products never really made any money though; it was just something that was ongoing for a while.

The products I worked on already existed but they were bringing out new versions. I didn’t come up with the original designs for those. Some of what I was doing was production engineering, like development really, getting it onto the board, ensuring the power supply was right, making it work and so on. I was working with an industrial design engineer and there were other engineers working on the mechanics.

Radio Chaos

The FM tuner I worked on and did the circuit layouts for had some problems. It got a bad review in a magazine and the result was that Sinclair decided not to redevelop it and dropped it. I think around about that time they stopped making the power amplifier too. It was a nice little amplifier which worked quite well, but I think they just didn’t want to put much engineering effort into it because it was a very small part of the company by then.

The problem with the tuner was that we weren’t using junction FETs; we were using bi-polar transistors, which resulted in cross-modulation when a large signal was coming in. If you had a proper aerial connected to it you could hear all the other stations mixing in with the one into which you were tuning, but the quality of the result was dependent on the relative signal levels.

If we’d used a junction FET like everyone else – which is a much more linear mixer and would not overload like that – for the sake of a few pence we would have had a product that worked! But Sinclair did not want to go down that route because he’d got it in his head that this circuit was the way to go. He always liked to have a very low component count, which was probably what made him successful in the early days. He prided himself in circuits that were minimal and did the job, except they didn’t always do the job! Sometimes putting a bit more in does a better job.

I don’t know if he knew if the product was a duffer, but the cross-modulation was a fundamental problem I couldn’t get around. The other problem was that the tuner wasn’t sensitive enough, so I increased the sensitivity which only aggravated the cross-modulation problem. Lots of companies have a product that doesn’t work too well so they discontinue it, but it should have got sorted before it got that far. I don’t know how many were sold but I even had one at home myself for a while.

That tuner was also sold in a plastic case that could be bolted on the front of a plinth using virtually the same circuit design. It didn’t have the extra sensitivity in it and wasn’t a bad product in a way, in so much as it was a tuner and worked.

There was a whole load of stuff sold like that: we would provide all the wiring in a kit and the customer could put it all together. I don’t think it was much of a seller but there was a lot of engineering in it. We even had special plastic moldings made to put all these circuit boards inside, and for that we had to have all the tooling made. It was a lot of work.

The hi-fi stuff did look nice. It was always black and smaller than you would think it could be. The amps were in an anodized aluminum die-cast black box. Clive’s brother, Ian Sinclair, was an industrial design engineer and designed the style of the knobs and what the whole thing looked like. Usually the casings were extremely small so you had to squash everything to get it in. But I think by 1974 all the hi-fi stuff was phased out.

LCD Experiments

Within a year of starting at Sinclair Radionics I was given a small project to do as a background task. Sinclair had decided to try making his own liquid crystal display, and was having prototypes made in a little workshop downstairs in the mill. LCDs work by using a small current to re-align crystals so that they appear either opaque or transparent. At that time LCDs were pretty new technology, but unlike everyone else, who were using an AC current to do the job, Sinclair wanted to pass a DC current, and was testing out ways to get that to work.

I suppose it made the electronics easier and the products potentially cheaper, but the problem was that it was acting like electrolysis – electro-plating the display and causing it to turn a dirty brown colour and sometimes start bubbling gas! So the engineers downstairs were putting this liquid between bits of glass and sealing it in somehow, and I was given the job of conducting tests on their samples.

I had to clear a little area at one end of my desk and create this set up with the display prototypes connected up to a voltage. I was recording the results every day and drawing out a current graph, commenting on whether there was discoloring. This went on for months and, basically, it was pretty obvious that it was failing. They were adding all sorts of substances in an effort to overcome the problem, but the thing that was giving best results was beeswax, and some of the ones with that in didn’t start going brown for months! Of course, beeswax is made of a whole load of compounds that you cannot reproduce reliably.

I was handling the things with the utmost care because it was rumored that the substances they were using were carcinogenic, and I wasn’t taking any chances. Health and safety wouldn’t have approved of it! It all went on for months with no one saying anything, until one day someone casually asked if I was still doing the tests, and said that if I was I may as well stop. We just cleared it all up and that was the end of it.

I think it was brave was to try out something like that. I guess it was done with a view to using it in calculators and watches, but I wasn’t told what it was about and just got on with it. TF

See parts 2 and 3 of Engineering for Sinclair elsewhere on this site.

Part 2 can be found here: Part 2