In Part 1, David explained how his interest in making things resulted in the establishment of Cambridge Consultants. In Part 2, David describes how the company faired after moving to a site in St Ives, which they shared with Sinclair Radionics.

Enderby’s Mill site, where Cambridge Consultants based many of their companies at the end of the 1960s.

“I’m not quite sure when Sinclair moved in to take over the mill,” says David thinking back to the start of the 1970s, “but the mill building itself was derelict when we arrived. Everything was in a pretty awful state, but there was an enormous amount of space.

“Clive was building up Sinclair Radionics in the mill building and we were trying to produce amplifiers in some of the other outbuildings in the area near the Mill house.”

At this time Clive Sinclair had no business interest in Cambridge Audio or Cambridge Consultants, even though his company was designing its own range of hi-fi equipment just a few yards away in the main mill building.

“He had his own audio amplifier which he called the System 2000,” David recalls, “but we got extremely good write ups for the Cambridge Amplifier. Undeservedly good, really, because it was a pig of a design! I mean, it was exactly the opposite of Clive’s. We had the name but we couldn’t make them very easily, whereas Clive didn’t have a name on that business at all then, but he could make them!

“I did a bit of product engineering on the Cambridge Audio amplifier and tried to get it made in a more up-to-date way, but there really wasn’t time to do too much and the whole group was basically pulled down by the working capital demands of the amplifier – at least that is what I reckon happened.

“Cambridge Audio was just part of the AIM Associates group, and the idea of separating companies into stand-a-lone entities was so that if one fell down it didn’t pull the others with it, but in reality it didn’t work like that because there was so much intercompany trading and everything was cross-guaranteed. It got terribly complicated.

“Anyway, in the end – in 1971 this was – we were about breaking even but the bank said enough is enough and they demanded the overdraught be shut down. The loan was paid back within a couple of weeks, or something like that, but it caused the whole group to go into receivership and the audio business was sold off to a chap called Colin Hammond. The AIM Electronics business went off to somebody else and Cambridge Consultants were taken over by Arthur D. Little.

“I should mention that before the bank demanded their money back and we shut down, Clive did chip in some money and become chairman of the group, and took an active interest in it, but it was too little, too late, as it were.”

A New Start

When the company broke apart in 1971, Tim and David went their separate ways. Tim eventually became interested in Green politics, while David continued involving himself with product development and production. His first post-Cambridge Consultants venture was, in some ways, an attempt to realize some of the ambitions he had had for Cambridge Audio, and was born out of an association with an aspiring designer.

“We went into receivership so everything was sort of sold off and I formed a company called Lecson Audio which, in 1974, got one of the design council awards,” David explains. “That was what I was doing for about three years, I think, and it was, again, very top-of-the-range high-fi equipment.

“I knew a chap called Bob Stuart who had previously entered a Cambridge Consultants quiz organised for Cambridge Audio. It was a technical quiz at an exhibition we used to have at Olympia and this chap, Bob Stuart, won hands down. So he got his free Cambridge Audio amplifier and that’s how we met up.

“When the receiver was appointed and I was looking around for things to do, I got in contact with Bob. He had always said that he wanted to design a better amplifier but he was working for Marconi, or someone like that, at the time. We also knew a chap called John Greenbank who was then working for the Gramophone classical music magazine, so they both joined me in this new venture, Lecson Audio, which had premises on Burrell Road in St Ives.

“We were financed by a local builder, and that went fine until his market – the building business – suddenly collapsed and he wanted to withdraw his money from the company. It was when credit rates suddenly increased. He had been building up a portfolio and he’d got assets and liabilities and the two were sort of balancing. It was fine when things were stable but as soon as the interest rates went up he was in trouble. I decided I had to get out of Lecson Audio but Bob kept going by getting funds from a city banker who was looking for a placing.

“So that sort of continued. Then Bob and a chap called Allen Boothroyd, who had worked on the design of the Lecson amplifier, went on to build the company Boothroyd Stuart who have a very big place in Huntingdon called Meridian Audio. And if you want to spend £20,000 on a pair of speakers, well, they are the people! Personally I think it is daylight robbery.”

Cambridge Instrument Company

David’s next move was to join an established company where the risk of things going belly up must have seemed much lower. The company in question was called, Metals Research, although while David was there it merged with Cambridge Instrument Company, which was similarly well-established in its field.

“The work was done down at Melbourne, but Metals Research, which was the driving force, was originally in King’s Street, Cambridge, amongst a whole rabbit warren of offices. They made equipment to look at the crystal structure of metals and tell you the number of inclusions, the size of the crystals and things like that.

“In general, you sectioned your steel and then put it under the microscope, which scanned the picture telling you the grain size, etcetera. And they built a very successful business out of this.

“Metals Research was actually owned by the Cole Brothers. E.K. Cole was, I think, the father of it all and he was behind the EKCO radios. Anyway, they took over Cambridge Instrument Company which had been struggling. The merger was being pushed by Wedgewood Benn and one of the government departments.

“Cambridge Instruments made electron beam micro fabrication equipment which you would use to write the whole circuit of a silicon wafer, so it had to work to incredible levels of accuracy. Cambridge Instruments were the first to produce the electron microscope and they continued to make instruments like that, selling for £50,000 or so. But they only made a few of each kind and it was a real nightmare because each one involved so many different parts. If, for example, you were using 14 BA screws – absurdly small screws – which you did for some of these things, you might only use a few of them, but you might also use the same tiny screw in another very expensive instrument, so just handling the stock for these things was extremely complex.

“Everything had a special purpose and was made with phenomenal accuracy. All the columns had to be aligned to fractions of a thou, so it was difficult.

“When I joined Metals Research/Cambridge Instruments I was working on a blood analysis machine which was being was done in conjunction with Addenbrooke’s Hospital in Cambridge. The concept was you took a sample of someone’s blood and it would tell you the red cell count, the white cell count, and it would also tell you the different kinds of white cells too. Of course this was done electronically, but the equipment also had to make the slides. What we were doing was separating the white cells from the red cells, making a slide, putting it under the microscope and the software had to decipher what was what, because a lot of these white cells – basophils, neutrophil and so on – almost grade from one end of the scale to the other. Two people would not agree what some of the cells actually were.

“I wasn’t involved in any software; I was just making the equipment. So the equipment was fed with a little file of blood, it shook it up, sampled it, separated the white cells, made the slides, put the cover slip on, put it under the microscope and then printed out the results! It was a big, complicated and expensive beast, and there were a lot of engineers working on it; it wasn’t just me.

“I also had a spell working on trying to find the errors in the electron beam micro fabrication equipment. That was enormous fun because the electron beam would only scan a very, very small area. It was like a cathode ray tube, only you were writing over something like half a millimetre square. It had to be able to scan a five inch wafer so to do that all these little half-a-millimetre squares had to link together with no errors and no overlaps. If there was a track that was a few microns wide, for example, it had to carry straight on from one to another, as it were.

“It also had stages. There was the optical stage which came from the States: that was a Hewlett Packard thing which had laser interferometers and was capable of measuring to a fraction of a wavelength of light. It was ridiculous!

“I spent a spell trying to sort out the errors that the machine made. For that we had to look at what the errors actually were and then deduce where they came from. What you found was that if anything warmed up, even by five degrees or something like that, it would make an enormous difference. You could actually calculate the expansion of things and tie everything back.

“I can’t remember too much about it now but I do recall that we got this equipment, which was for one of the big American companies called Rockwell, so that it was working really well, but when it was taken for packing it was dropped, so it was back to square one, practically!”

Metals Research were based at 91 Kings Street, in what David describes as “a whole rabbit warren of offices.” The address is now a shop, as seen on the right.

Tube Time

While David was working first on his Lecson project and later for Cambridge Instruments, Clive Sinclair’s Sinclair Radionics had begun to phase out its hi-fi business and was enjoying the success of its pocket calculators. The digital ‘black watch’ was still a few years off, as was the ZX80 home computer, but the TV1A pocket television, which Sinclair had prototyped way back in 1966, was in production. The television’s costs were detrimental to the company, causing it to make a loss, and not even the lower-cost, plastic-cased TV1B and variants, the TV1C and TV1D, could rescue matters. Things were so bad that the National Enterprise Board, known as the NEB, stepped in to save the company, offering a massive injection of capital on the condition that it also took partial control of the business.

Undaunted, Sinclair still planned to take his pocket television concept a stage further, this time replacing the Telefunken tube with a bespoke ‘flat’ tube, which required the cathode beam to bend at a right angle.

To help take the state-of-the-art tube from the prototype stage into production, Clive approached David, asking him if he would join the team.

“It was during my spell at Cambridge Instruments,” recalls David, “when Clive said ‘Look, I’ve got this flat tube and I need a million of them a year.’ So he encouraged me to join Sinclair Radionics to work on its production. I had an office on the top floor of the mill that I shared with CRT consultant Tony Krause. That was some time around 1975, or something like that – I’m not entirely sure. But Clive told me he had got backing for the tube from the National Research Development Council and the National Enterprise Board, but actually it was when the whole place was falling apart! There were the most furious arguments going on because the NRDC and NEB thought that Clive was conning them. Having just joined I was absolutely appalled by this, and, of course, there wasn’t a flat tube!

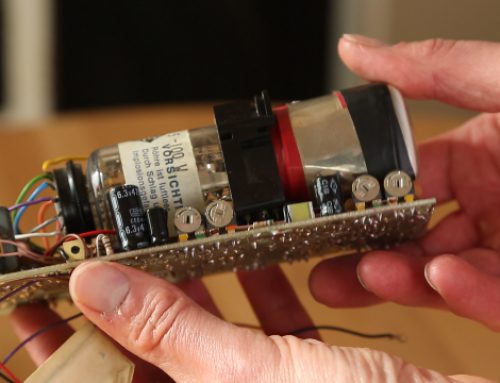

“The thing that I saw on the top floor of the mill that first made me think that it was possible was somebody else’s tube; specifically an AEG Telefunken CRT, built inside a round tube and arranged so that it looked as though what Clive was proposing – which was to bend the beam at a right angle – did actually work. I’m not sure when amongst all of this the company bust up actually occurred, but when it did Clive had to leave the mill and go to King’s Parade in Cambridge, taking with him Jim Westwood, Brian Flint and a few others. I stayed behind to look after the making the prototype tube.” TF

Part 1 of our interview with David can be found here: Part 1

Part 3 of our interview with David can be found here: Part 3